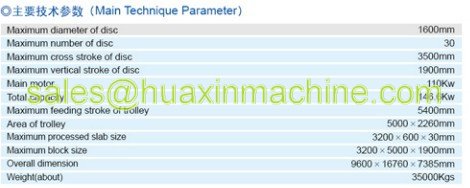

MZ600/30 Stone Sawing and Cutting Center is used to process the specification slabs into mass production. It can finish the automatical operation from sawing the block , cutting off to unloading slabs, which reduces HR cost. MZ600/30 Stone Sawing and Cutting Center consists of HMJ160/30 Gantry Multi-disc Stone Sawing Mahine , HMPQ60 Gantry Level Cutter and HZX120/19 Automatic Slab Unloading Machine.

Its main features as follows:

1.Sawing machine adopts double-column gantry structure.The overall rigidity is good; it can install 30 pcs of φ1600 saw blades. The speed of crosswise walking can reach 10m/min。The length of working table reaches 5m, it can process the multi-block stone materials one time, reducing the non-cutting time which the stone materials lifts. Therefore this machine’s productivity and is better than ordinary sawing machines. At the same time, because using the cutting pattern which shallow cutting and feeding quickly, the service life sawing blade obtains the big enhancement.

2.The crosswise walking of this machine adopts straight guide-rail, it adopts PLC controlling system. Horizontal, lengthways and vertical operating all adopt revolve coder control system. Equipment movement and control accuracy are high and reliable.

3.Vertical movement and the movement of working table in front and back establish hydraulic locking device. While sawing, the locking device working ,the crossbeam and the column are locked tightly and together, the working table and the guide–rail are locked tightly and together. This device raise the rigidity of whole machine when cutting, it is good at raising the processing accuracy and efficiency.

4.The vertical guide-rail、guide-screw and carriage part adopt a grease concentrated dielectric lubricate system. The lubrication effective is high, the equipment accuracy keeps good, and reducing the maintaining time everyday in the meantime.

5. At the safety aspect, this machine increases the protection device to protect the vertical screw nut, the protection device to protect the vertical screw not to flee, and the protection device to protect the cooling water pressure. These devises promise the equipments working safety and reliable.

6.This machine adopts gantry structure, with reasonable structure and stable working conditions. The saw blade is fixed on the main spindle, it can realize the rising and falling、the back and forth slicing 、feeding movement and the cutting movement along the crossbeam, it can complete the multi-floor cutting and multi-slice cutting. It can work with the stone saw machine at the same time.

7.The cross walking adopts frequency controlling , it can be suit for the different kinds of stone plate. At the same time, it can realize the speed reture of saw blade.

8.The vertical instructure and the longitudinal instructure adopt code device controlling, it make the machine has high efficiency and stable operation.

9.Vacuum sunking disc has the such operations , lifting , forward & backward , turning , advancing & retreating , ect . It covers a wide range of movements and can realize operating automatic slab unloading while the sawing blades are cutting .

10.Air system adopts vacuum elements exported . What’s more , it uses stander square pipe to form vacuum power accumulator , which makes air system run reliably and move quickly .

|