FUNCTIONS

It can be used to de-hull pumpkin seeds and remove shells.We innovated old-fashioned de-huller to get higher processing capacity and lower rate of broken kernels,The seeds are processed in a continuous circle.Un-hulled seeds can be delivered automatically to next round processing.Shells are collected by negative pressure insteda of blowing-out so as to decrease dusts.

These are several separating screens attached with the machine,which enables processor to separator,and electric control cabinet.

COMPONENT

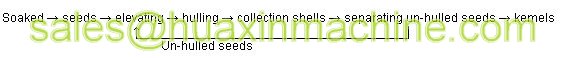

The equipment consists of feed-in hopper,bucket elevator,huller,shells collector,un-hulled seeds separator,and electric control cabinet.

PROCESSING

MAIN PARAMETER

Power:4.5KW(380V)

INTEGRAL KERNELS RATE:95% min.(Brokrn kernel is less than 1/2 of whole kernel)

Content of seeds in the kernels:2% max.

Content of seeds anf kernels in the shells:0.3% max.

Production rate:100kg/hour

Occupied area:5.5m*3.0m

Height:3.3m

Weight:3.0t

Operator:2persons |